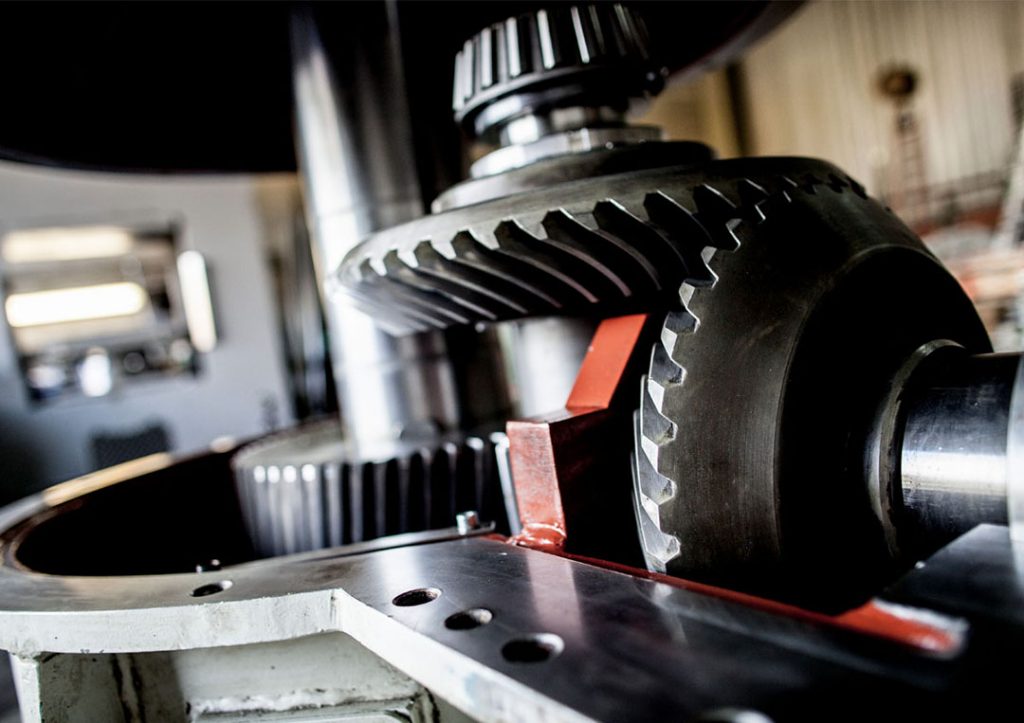

Repair and maintenance solutions for all reducer gearbox types and brands

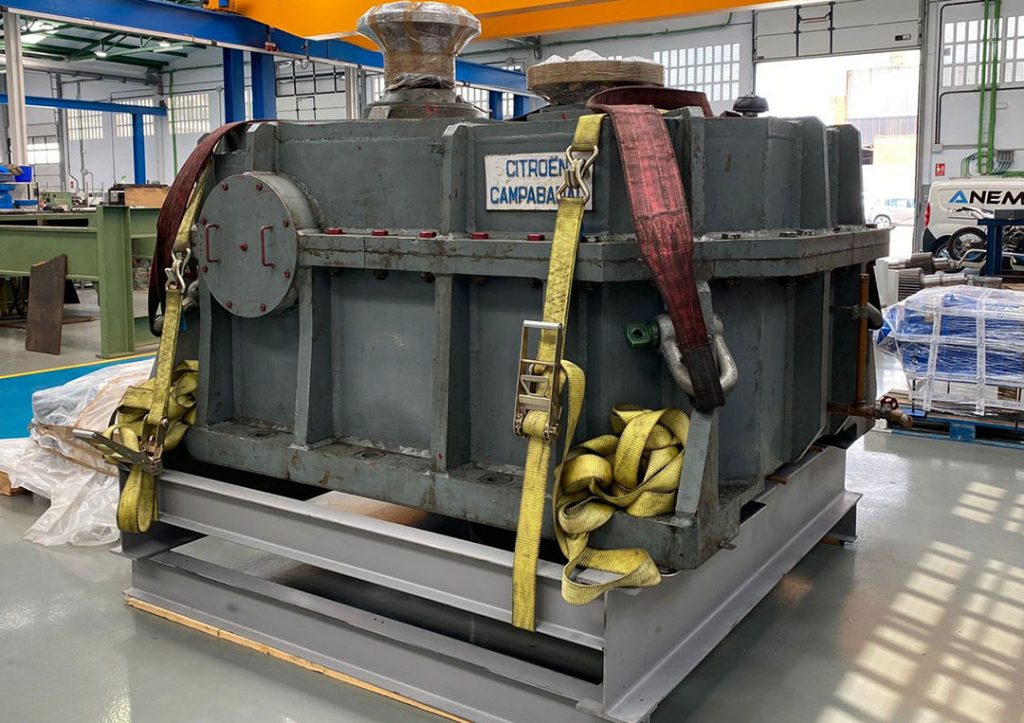

ANEMGROUP are experts in repairing and maintaining all brands of mechanical power transmissions, current and discontinued alike. We can provide service from our specialised facilities or, in some cases, on-site at our clients’ facilities.

Improvement projects

We analyse and redesign in order to modernise and repower equipment, improving the original performance while offering different solutions and processes, adapting to the client’s need at all times.

Urgent repair service, technical assistance and after-sales service

We are your transmissions partner, always there for our clients to offer advice with the utmost urgency.

Study of the causes of the breakdown

We have a team of highly specialised engineers with extensive experience in repairs and maintenance. We know how to detect the cause of equipment problems and work on improving them to avoid recurring breakdowns, helping clients to cut down on their downtime costs.

Diagnosis

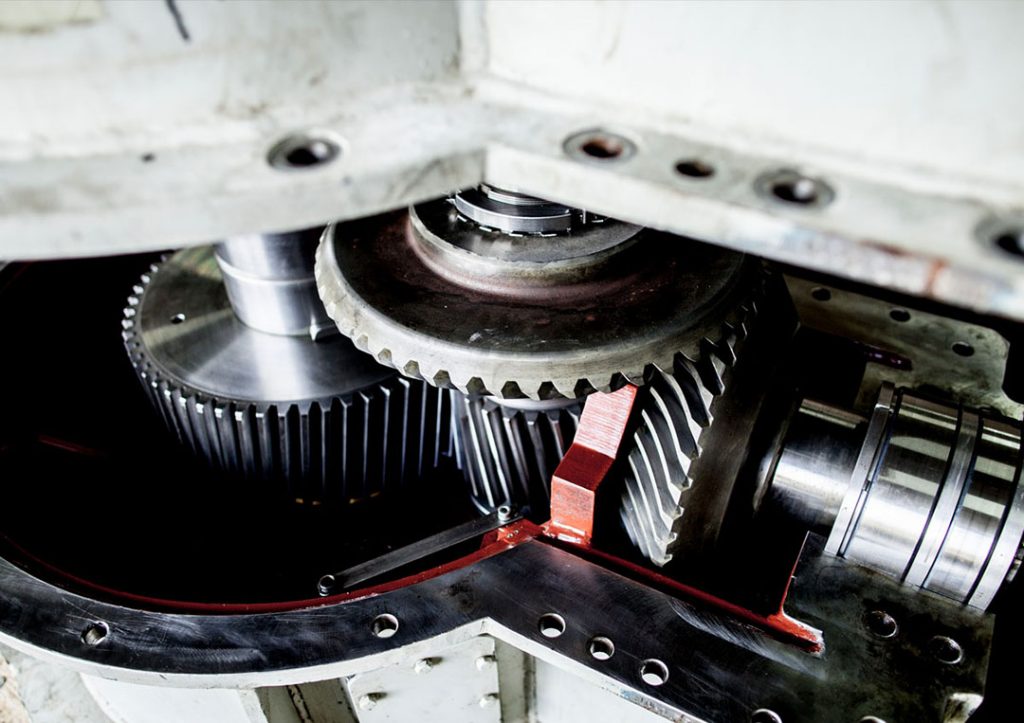

Any intervention begins with a thorough diagnosis to determine the condition of the equipment and the causes of the breakdown.

The following methods can be used for this purpose:

The following methods can be used for this purpose:

- Magnetic particle / liquid penetrant testing (surface crack location)

- Ultrasound (locate internal fissures)

- 3D and/or arm measurement of geometries

- Conventional tests such as wobble and touch checking

- Destructive and non-destructive analysis of materials (chemical, tensile, hardness, heat treatment, etc.).

Based on the results obtained, a report is drawn up and the necessary actions are taken to repair and ensure correct operation of the part.

For our technical team, it is as important to repair the breakdown as it is to understand its causes, in order to prevent a recurring issue.

For our technical team, it is as important to repair the breakdown as it is to understand its causes, in order to prevent a recurring issue.

Corrective, preventive and predictive maintenance

We carry out corrective maintenance with the utmost urgency in the event of a breakdown, in order to minimise downtime as much as possible if the client does not have a spare reducer gearbox.

We plan preventive maintenance of the reducer gearboxes in order to check the most critical and most worn-out components of the reducer gearbox and carry out the necessary actions to keep it in perfect condition.

We also offer predictive maintenance. It is of the utmost importance to carry out this type of maintenance in order to control how the reducer gearbox operates and to be able to correct possible faults as well as prevent significant breakdowns.

We plan preventive maintenance of the reducer gearboxes in order to check the most critical and most worn-out components of the reducer gearbox and carry out the necessary actions to keep it in perfect condition.

We also offer predictive maintenance. It is of the utmost importance to carry out this type of maintenance in order to control how the reducer gearbox operates and to be able to correct possible faults as well as prevent significant breakdowns.

- Gear wear monitoring

- Vibration analysis

- Alignment controls